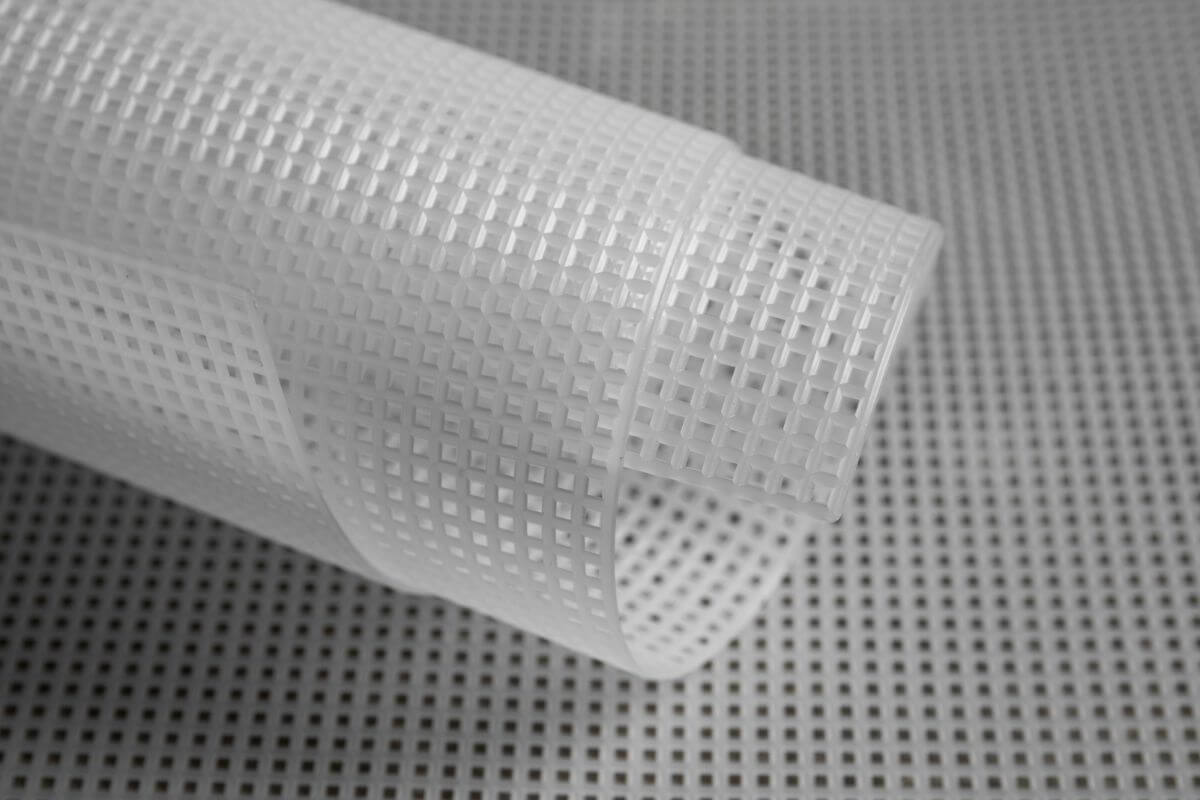

Innovation and product differentiation play crucial roles in gaining a competitive edge in the manufacturing industry. One such manufacturing technique that has gained significant attention is plastic overmolding. This process involves combining two or more different materials to create a single, unified component with enhanced functionality and aesthetics.

Choosing the right materials for plastic overmolding is a critical aspect of the process. It determines the final product’s performance, durability, and overall success in meeting the desired requirements. Whether you’re a product designer, engineer, or manufacturer, understanding the key considerations in material selection is paramount.

This article serves as a comprehensive guide to help you navigate through the intricacies of selecting suitable materials for plastic overmolding. We will explore the factors that influence material choices, delve into popular material combinations, and provide valuable insights into optimizing your overmolded products.

Substrate Material

The substrate material forms the foundation of a plastic overmolded component, providing strength, stability, and compatibility with the overmolded material. It plays a crucial role in providing structural integrity and dimensional stability. When selecting the substrate material, it is essential to consider factors such as strength, rigidity, and compatibility with the overmolded material.

The substrate material should possess sufficient strength to withstand the injection pressures and temperatures involved in the overmolding process without deformation or warping. It acts as the primary support for the overmolded material and should provide a stable foundation to ensure proper bonding between the two materials. Additionally, the substrate material should have good chemical resistance to withstand exposure to various environments and substances.

This being said, careful consideration of the substrate material’s mechanical properties, chemical resistance, dimensional stability, and compatibility with the overmolded material is crucial to ensure a successful overmolding process and the production of high-quality overmolded parts.

Overmold Material

The overmold material is another critical component in the plastic overmolding process, as it provides additional functionality, aesthetics, and tactile properties to the final product. Typically, overmold materials are soft elastomers or flexible thermoplastic materials that are injected over the substrate material to create a seamless and integrated component.

Among the key considerations when selecting the overmold material is its compatibility with the substrate material. The overmold material should exhibit good adhesion and cohesion properties, ensuring a strong bond with the substrate material. This compatibility ensures that the overmolded layer adheres securely to the substrate, preventing delamination or separation.

Additionally, overmold materials can contribute to the visual appeal of the product by providing color, texture, or branding elements. They offer opportunities for customization and differentiation, allowing manufacturers to create visually striking and aesthetically pleasing designs.

Compatibility

Compatibility is yet another crucial factor to consider when choosing materials for plastic overmolding. It refers to the ability of the substrate material and the overmold material to form a strong and reliable bond during the overmolding process. Incompatibility between these materials can lead to adhesion issues, delamination, or poor bonding, compromising the structural integrity and functionality of the final product.

Material compatibility encompasses various aspects, including melt compatibility, chemical compatibility, and physical properties compatibility. Melt compatibility refers to the ability of the substrate material and the overmold material to melt and flow together during the overmolding process. If the melt temperatures of the two materials are significantly different, it may result in poor adhesion and incomplete bonding.

Chemical compatibility is another essential consideration. The substrate material and the overmold material should be chemically compatible to ensure a strong bond and resistance to chemical exposure. If the materials have different chemical compositions, they may react negatively with each other, leading to reduced adhesion or even material degradation.

Moreover, physical properties compatibility plays a significant role in determining the overall performance of the overmolded component. The materials should have similar physical properties, such as coefficients of thermal expansion, flexibility, and hardness, to prevent issues like warping, dimensional instability, or material mismatch.

Mechanical Properties

Another crucial factor to consider when choosing materials for plastic overmolding would be the mechanical properties. These properties directly influence the strength, durability, and overall performance of the overmolded component. Key mechanical properties to evaluate include tensile strength, impact resistance, hardness, flexibility, and fatigue resistance.

And in conjunction with the specific application requirements and performance expectations, it is important to evaluate the mechanical properties — thus should align with the intended use, anticipated environmental conditions, and functional demands of the overmolded component. As you carefully consider and match the mechanical properties of the chosen materials, manufacturers can ensure that the overmolded product meets the necessary strength, durability, and performance criteria.

Chemical Resistance

Chemical resistance refers to the ability of the substrate material and the overmold material to withstand exposure to various chemicals, solvents, and substances without undergoing degradation or damage.

Different applications may involve contact with different chemicals, such as oils, fuels, cleaning agents, or corrosive substances. Therefore, it is crucial to choose materials that can resist chemical attack and maintain their integrity, performance, and appearance over time.

During the overmolding process, the substrate and overmold materials come into direct contact with each other, and they should exhibit compatibility in terms of chemical resistance. If the materials have different chemical compositions or react adversely to each other, it can lead to reduced adhesion, material degradation, or even failure of the overmolded component.

The selected materials should then be able to withstand prolonged exposure to the specific chemicals encountered in the intended application. Manufacturers should consider factors such as the concentration, temperature, and duration of chemical exposure when assessing the chemical resistance of the materials.

Key Takeaway

The process of choosing the right materials for plastic overmolding requires a comprehensive understanding of the specific application needs, thorough assessment of material properties, and collaboration with material suppliers and experts. With careful consideration and informed decision-making, manufacturers can achieve successful overmolding outcomes that elevate their products in terms of performance, aesthetics, and market competitiveness.

I recently tried [url=https://cbdforlife.us/products/cbd-roll-on-oil-original ]cbd pain roll on[/url] in place of the principal ever and I be compelled assert, I’m impressed with the results. I felt more tranquil and at appease, and my apprehension was significantly reduced. The gummies tasted mammoth and were peacefully to consume. I’ll unequivocally be using them again and would recommend them to anyone looking in compensation a health route to alleviate grief and anxiety.